With 30 years of sectoral experience and expert staff, Metser Coating Industry Trade LTD. STI

Plasma Coating Applications

Coatings made by the plasma method are obtained by using ceramic powders (Chromoxide, Aluminoxide, Zirconium Oxide etc.) in various alloys, coatings that can work at high temperatures that are resistant to wear and corrosion.

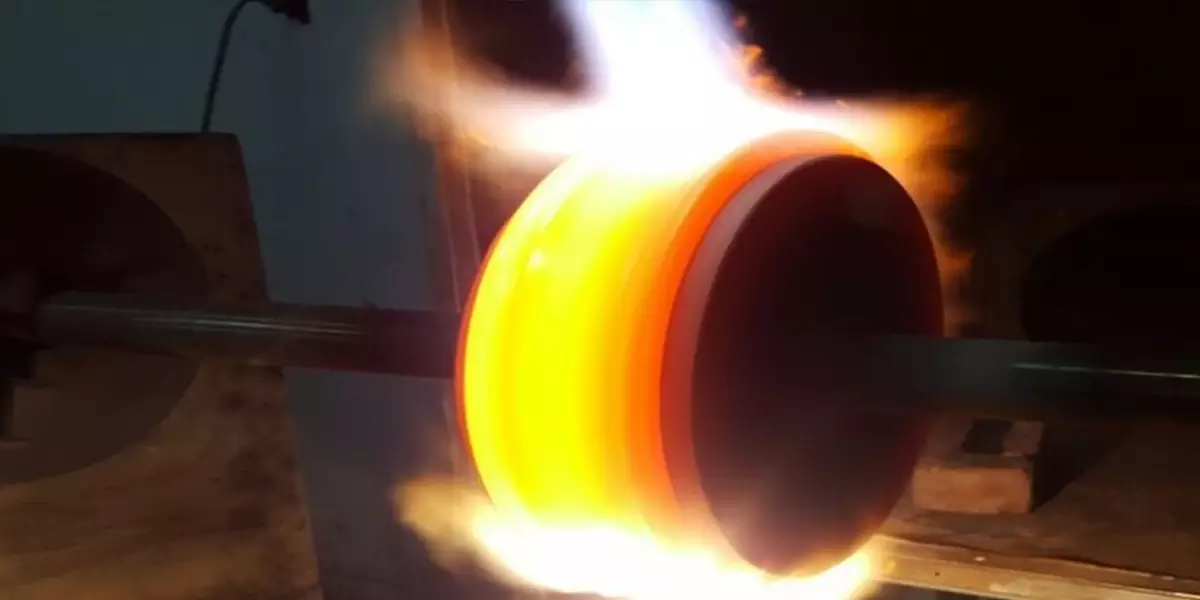

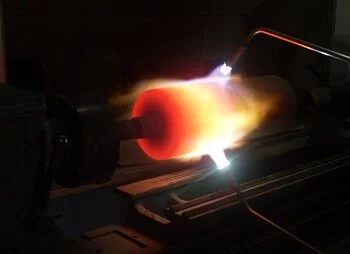

HVOF Coating Applications

In the coatings made by the HVOF method, hard coatings with frequent texture, Abrasive abrasion and corrosion resistant are obtained by using metal powders (Tungsten Carbide, Chromium Carbide and Cobalt ) in various alloys.

Wire Flame Spray Applications

In the coatings made by the wire flame spray method, various wire alloys (Molybdenum, Stainless Copper, Aluminum, Zinc, Bronze, Babbit) sprayed with oxy-acetylene-propane flame and high-pressure air are used to obtain fillings for repair purposes, wear-resistant and corrosion-resistant coatings.

Arc Spray Applications

Various wire alloys (Molybdenum, Stainless Copper, Bronze) that are pulverized by electric arc and high pressure air in coatings made by arc spray method. By using Aluminum, Zinc, Babbit), fillers for repair purposes, wear-resistant and corrosion-resistant coatings are obtained.

Powder Flame Spray Applications

Powder flame method coatings made with various metal powders (Nickel, Cobalt and Tungsten Carbide) and ceramic powders of various alloys (Chromoxide, Aluminum Oxide, Zirconium Oxide) are used to obtain fillings for repair purposes and coatings that can work at high temperatures resistant to abrasion, cavitation, corrosion, metal-to-metal friction.

Metalizing

By using the wire flame and Arc spray methods, coatings that can work at high temperatures resistant to corrosion are obtained by using various base material surfaces (Zinc, Aluminum and Special alloy wires).

ISO 9001:2008

Certified

At High Standards

Workmanship Quality

30 Years

Knowledge and Accumulation

Who Are We?

Our company provides services on protective and restorative coatings by choosing the most suitable material and coating method against abrasions caused by working conditions for facilities in sectors such as Textile, Glass, Iron, Steel, Petrochemical, Paper, Printing, Packaging, Chemical, Wire Drawing, Defense, Energy and Metal/Manufacturing.

Why Metser Coating?

Quality and Technological

Our company sees the delivery of quality and timely products as a strategic element and acts by believing that quality will be a determining factor in the works. It has adopted the principle of always moving up the line and increasing the competitive power of the company with continuous development by constantly following technological innovations without sacrificing quality and time.

Industry Experience

With 30 years of experience and our expert staff, we aim to offer quality and economical price to our customers, and we continue our work in this regard.